1.Automatic Feeder: Adopts offset feeder with advanced pneumatic side lay, which fastest can feed around 15000 sheet/h. Non-stop and pre-stack feeding can improve work efficiency.

2.Overlapping Regulator: Adopts Servo system to control the overlapping that guarantee accurate and stable, and make sure the overlap error within 2mm.

3. Drying and Heating System: Bulk 800mm diameter drying roll with Teflon coating, that could bring the highest glue drying effect, Large heating roll by electromagnetic heating plus oil heating, guarantee the heating efficiency and make sure laminating quality when run in high speed.

4.Main Machine Body: Thicken machine wall (25mm thickness) enhances stability and for long time service life.

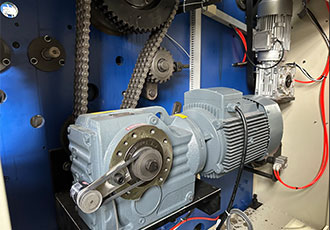

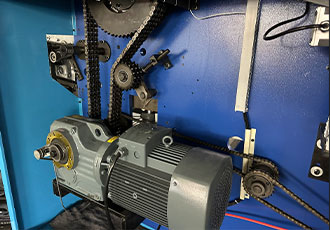

5. Three rows chain Driving System: Special structure design in minimum transmission line, adopts three rows chain to drive the laminating unit to guarantee the high laminating speed with low noise.

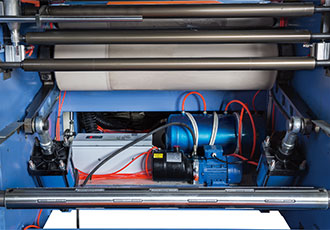

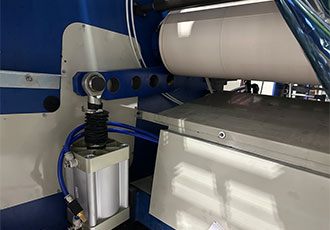

6. Pneumatic Pressure System: fully pneumatic system to control the laminating pressure, the pressure would highly uniform and easy to adjust.

7.Man-Machine Interface System: Advanced 10inch color screen with PLC system makes the operation easy and convenient.

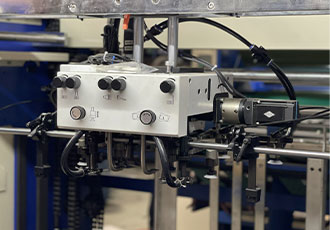

8. Hot Knife: Adopts double servo systems to control cutting precision, and the knife is under 600 degrees heating treatment that would never shape change. Top Baumer sensor make sure the machine running in high precision

9. Anti-Curvature Device: Avoid paper curvature and make the paper smooth, especially for thin paper.

10. Corrugated、 Delivery: Better and easier for collecting paper.

11 Car Body: Whole machine cover adopts car body, glossy and wear-resisting.

12 Automatic Stacker: Full automatic with sensor to rise and down the paper pile, heighten structure that can load paper pile height in 1060mm, side and front tidy devices to make sure paper pile collect well.

|

Max. sheet size |

1080*1000mm |

|

Min. sheet size |

350*295mm |

|

Paper thickness |

Disc Cutter 80-500Gsm Hot Knife >127gsm |

|

Height of feeding pile |

1160mm |

|

Height of stacker pile |

1160mm |

|

Machine speed |

105m/min |

|

Working speed |

Disc cutter 80-100m/min Hot knife 70-80m/min |

|

Machine power |

85kw |

|

Working power |

30-35kw/h |

|

Dimension of machine |

L11000×W3100×H3100mm |

|

Machine weight |

10500kg |

|

Available size W780*L780mm/1000mm W 1080m * L 1000mm//1100mm/1300mm/1500mm/1700mmm W 1280m * L 1000mm/1100mm/1300mm/1500mm/1700mmm W 1480m * L 1000mm/1100mm/1300mm/1500mm/1700mmm |

|

|

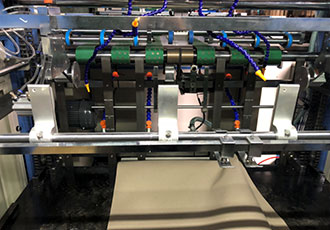

1. Automatic Feeder We adopt Servo controlling offset feeder head (max speed 15000sheet/ hour), that makes the sheet feed more stable and smoother. The feeder is non-stop type with pre-stack guide device, which can keep the machine running when run out the paper pile. German Becker vacuum pump guarantee the stable feeding. |

|||

|

|

||

|

2. Sheet Delivery Platform Servo system to control the side lay and front lay connect with feeder in high precision, that guarantee the overlapping error within 2mm. |

|||

|

|

||

|

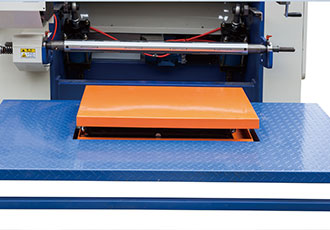

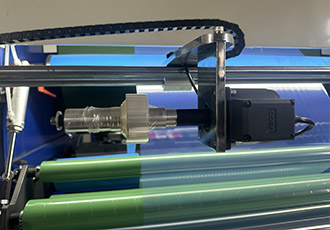

3. Laminating Unit Heating roller by electromagnetic heating plus oil heating, double heating systems guarantee the prompt pre-heating and make the temperature to 180℃ and can keep constant temperature in high speed laminating. Pressure rubber roller controlled by fully pneumatic system, the pressure would highly uniform and easy to adjust without bubbles、spots or wrinkle. |

|||

|

|

||

|

4. Glue Coating unit High precision processing double metal rolls glue coating system to support low glue consumption (2-4g/m2) Adjustable glue coating quantity to match different materials and running speed. Outside moving glue coating unit: the glue coating rolls are moved outside of machine (drying unit), so the glue will not dry on rolls because of hot air. |

|||

|

|

||

|

5. Drying system Special design IR lamps set inside of drying roll, that make the glue drying fast but with low power consumption. Blowing fans plus exhaust fan recycle the hot air and energy saving Teflon coating surface to uniform the temperature and glue Sticking prevention that easy for cleaning and maintain. |

|||

|

|

|

||

|

6. Film Unwinding Install air shaft for film unwinding with auto tension controller. Special design for big diameter film roll and the roll can be adjusted to right and left. |

|||

|

|

||

|

7. Waste Film Slitting and Rewinding Moveable waste film rewinding to modify the jumbo film width that can fit for paper sheet size. |

|||

|

|

||

|

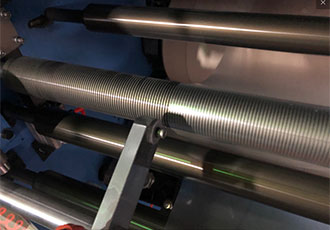

8. Disc Cutter With Pneumatic System Multiple blades disc cutter for BOPP film with pneumatic sheet separating, that makes the laminated sheets without margin, and prepare for next process. Two sheeting roll system can effectively sheet paper, special concave-convex roll make sheet smoothly and antislip. |

|||

|

|

||

|

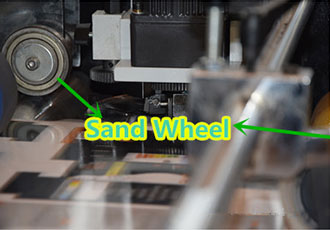

9. Sand Wheel Sand wheel instead of disc cutter for middle side flim lamination, that prepare for pneumatic sheeting. |

|||

|

|

||

|

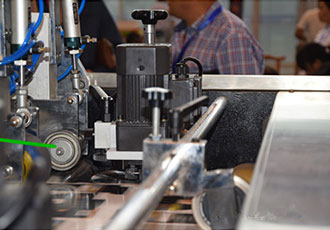

10. Hot Knife Baumer Sensor with servo system make sure the knife cutting in high accuracy. 600 degrees heating treatment hot knife blade make the strong body with long service life. Touch screen connect with PLC system that keep same step with main machine. |

|||

|

|

||

|

11. Three rows chain with gear box driving system For the main laminating part adopts three rows chain with gear box driving system, that support machine run in high speed with high precision and low noise. This structure also support machine run in long time but keep stability. |

|||

|

|

||

|

12. Fully Pneumatic laminating pressure system The machine use pneumatic pressure for laminating pressure that would guarantee laminating effect, also have sensitive pressure adjustment and keep machine running in clean condition. |

|||

|

|

||

|

13. Pneumatic guiding system Removable guide wheels with pneumatic system to adjust the pressure that easy to operate and maintain. |

|||

|

|

|

||

|

14. Corrugated Delivery Corrugated delivery with conveyor belt that better and easier for collecting paper. |

|||

|

|

||

|

15. Automatic Stacker Fully automatic with sensor to rise and down the paper pile Heighten structure that can load paper pile height in 1060mm Side and front tidy devices to make sure paper pile collect well. |

|||

|

|

|

||

|

16. Hydraulic lifting for loading film roll |

|||

|

|

|

||

Max. width 1050mm

Up to 80-100m/min

Max. sheet size 1080*1000mm

Up to 105m/min

Max. sheet size 1080*1000mm

Up to 105m/min