1. Automatic Feeder: Adopts offset feeder with advanced pneumatic side lay , which fastest can feed around 15000 sheet/h. Four suck and four feeding system to guarantee paper sheets deliver smoothly. Non-stop and pre-stack feeding can improve work efficiency.

2. Double sheets or numerous sheets detection system: The machine would auto stop while feeding numerous paper sheets

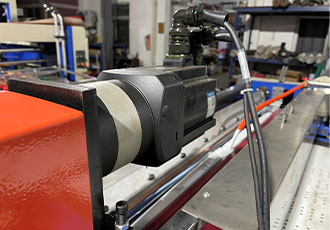

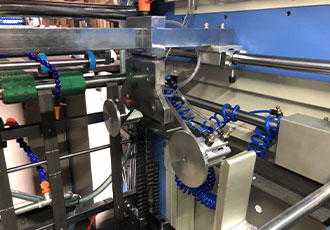

3. Servo coating head: The coating head adopts servo control system. Inversion three roll system for coating unit that make sure the uniform coating and glue saving.

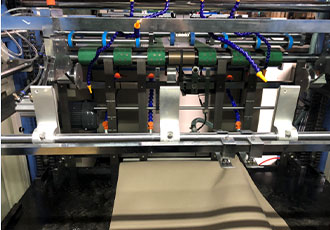

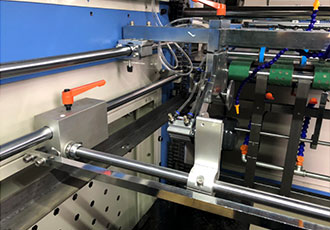

4. Synchronous belt driving: The coating unit adopt synchronous belt and gear structure to drive machine that make machine coating in high precision and keep steady running.

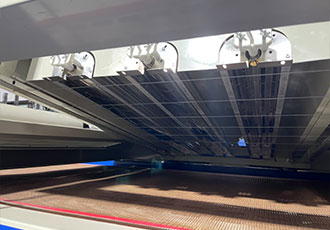

5. UV Curing unit: The machine comes with three sets UV lamps; three sets UV lamps are mutually independent that can turn on lamp quantity as requirements. And the power of UV is adjustable that can change from 3kw-12kw

6. Car Body: Whole machine cover adopts car body, glossy and wear-resisting.

7. Automatic Stacker: Fully automatic with sensor to rise and down the paper pile, side and front tidy devices to make sure paper pile collect well.

8. Auto alarming system: if paper wraps in coating unit, machine will auto stop

9.UV Curing unit safety device: UV lamps will auto turn off if machine stop and drying unit will auto rise

|

Model |

SGZ-1200C (Single head) |

|

Max. Sheet Size |

1150mm(W)×1200mm(L) |

|

Min. Sheet Size |

350mm(W)×350mm(L) |

|

Paper Thickness |

230-500GSM 157-500Gsm (with air knife) |

|

Roll Width |

1200mm |

|

Max Working Speed |

80-100m/min |

|

Infrared lamp Power |

2kw×18 |

|

Coating head power |

2.2kw×2 |

|

UV Curing Power |

3kw-12kw×3 Stepless power adjustment |

|

Machine weight |

8000kg |

|

Overall size |

18000*2200*2150mm |

|

1. Automatic Feeder We adopt offset feeder head (max speed 15000sheet/ hour), that makes the sheet feed more stable and smoother. The feeder is non-stop type with pre-stack guide device, which can keep the machine running when run out the paper pile. German Becker vacuum pump guarantee the stable feeding. |

|||

|

|

||

|

|

||

|

2. Coating Head We adopt special servo system to control the rubber roll that make the coating with higher precision and guarantee the varnish quality. Besides, as the wearing of rubber after daily running, servo system could change the rate to adjust the rotate speed that could make sure coating unit working steady and no need change the rubber roll. |

|||

|

|

||

|

|

||

|

3. Driving structure The coating unit adopt synchronous belt and gear structure to drive machine that make machine coating in high precision and keep steady running. |

|||

|

|

||

|

4. Touch screen with PLC and Electrical parts |

|||

|

|

||

|

5. UV Curing unit The machine comes with three sets UV lamps, three sets UV lamps are mutually independent that can turn on lamp quantity as requirements. And the power of UV is adjustable that can change from 3kw-12kw |

|||

|

|

|

||

|

|

||

|

6. Cooling system Low noise cooling fan and make sure paper sheet chilling fastly |

|||

|

|

||

|

7. Waste Film Slitting and Rewinding Moveable waste film rewinding to modify the jumbo film width that can fit for paper sheet size. |

|||

|

|

||

|

|

||

|

8. Automatic Stacker Full automatic with sensor to rise and down the paper pile Heighten structure that can load paper pile height in 1060mm Side and front tidy devices to make sure paper pile collect well. |

|||

|

|

||

|

|

||

|

9. Air knife Special for thin paper for steady delivery |

|||

|

|||

|

|

Max. width 500mm

Up to 0-100m/min

Max. width 1150mm

Up to 80-100m/min

Max. width 700mm

Up to 0-30m/min

Max. width 900mm

Up to 0-30m/min