As the growing requirements of diversification laminating, our ZFM-1080BN is launched in the market, and quickly win excellent public praise.

ZFM-1080BN is our top configuration model that more than 60% customers choose this model. The machine comes with multi-functions that could apply to dry water based glue lamination (or we can see hot glue lamination), thermal lamination, and also available for oil base glue lamination and some colored glue lamination.

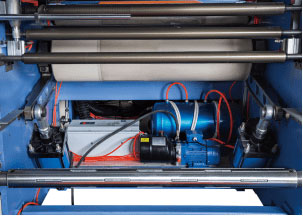

Different from traditional laminating machines, our ZFM-1080BN adopts fully Pneumatic system. We use pneumatic cylinder with leverage structure that not only increase the lamination pressure, but also bring a uniform pressure system and make it more sensitive pressure adjustment system. Compare with traditional hydraulic system, pneumatic system will be much stronger and steady and also bring a clean machine running environment.

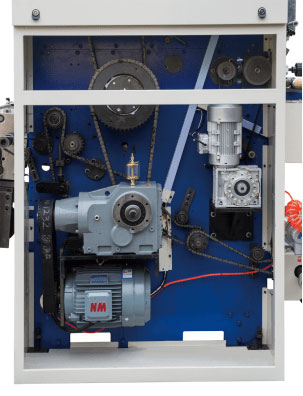

As to the driving system, we replace the old two rows chain driving system and use gear box with synchronous belt plus three rows chain system. With this huge improvement, the machine jump to three-digit number steady working speed 100m/min and get a renovation in overlapping accuracy to 1.5mm. Moreover, by this strong structure the machine could keep running 5 years, 10 years even longer without doing any mechanical structure adjustment.

Low power consumption could be our biggest selling point. We developed special low power quartz heating tube and enlarge the blowing system. To make sure the glue drying efficiency, we reduce the heating power and increase blowing fans and exhaust fans system, our machine could run only in 20-25kw/h that saved at least 30% energy. Of course, we install the muffler to make sure machine run in low noise and control it lower than 85db.

The machine adopt high configuration offset feeding system that could feed Max 18000pcs/h. And with pneumatic delivery system and auxiliary blowing system in automatic stacker, the machine could run for big range thickness sheet materials from 70gsm to 500gsm that covered 95% paper materials in the market.

After several years of continuous development and testing in hundreds of machine, our flying knife (chain knife) being very mature and steady. We use servo system with ultrasonic probe to detect and cut the laminated sheets film with high accuracy. Free standing touch screen in flying knife unit make the operating easily and show the alarm code in touch screen when machine run in errors. For the whole laminator, after installing flying knife, the machine will suitable for various film materials lamination, such as PET, PVC, BOPP, CCP, Metalized film, holographic film, etc.

Comes to glue coating unit, the machine adopts double chroming metal rolls with rubber drawknife to instead of anilox roll glue coating system. The advantage is we can adjust glue coating thickness as different products and production speed. High precision chroming metal rolls under quenching treatment bring the excellent uniform glue coating that could run in 2-3 g/m2, and also available for black glue or some other colored glue coating without any spots or lines. What’s more, this advanced glue coating system most have no lamination for different water based glue that could widely use for thick and thin glue. And in the whole glue coating unit include glue plate, guide rolls, drawknife holder and drying roll we all do the teflon coating on the surface. By teflon coating, the glue will not easy to stick on the surface and very easy for cleaning in daily production.

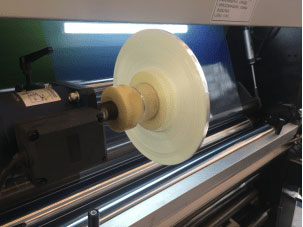

Film unwinder unit also with a lot humanization designs. Exclusive hydraulic lifting system is convenient for loading and unloading heave film rolls. Movable independent film slitting with auto tension controlling system that could adjust the film roll width and cut unsmooth edge to match the paper sheets.

Xinxing machine is concentrate on research and Development of film laminating machine, and we will keep innovating and creating more functions machine.