Configuration & Functions

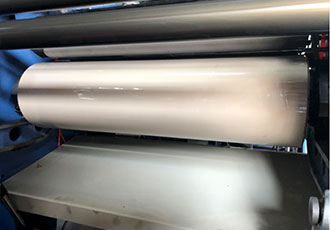

1. Shaftless Unwinding: The unwinder adopts shaftless feeding system that both suitable for 3inch and 6inch paper core and could support big jumbo roll. Shaftless unwinder is easy for loading and unloading to support max 4000kg.

2. Compact machine structure design that would be easy for cross the paper materials in machine and save the materials waste.

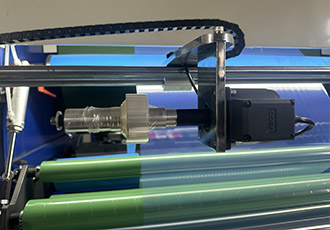

3. Ultrasonic Web guide: Adopts ultrasonic web guide system, that with sensitive correction sensor.

4.Teflon coated drying roll: Exclusive treatment of drying roll with Teflon coating that make the roll surface smooth and glue stickless. Compare with chrome plate, the temperature will more balanced.

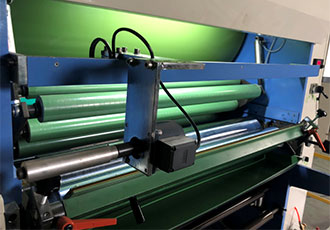

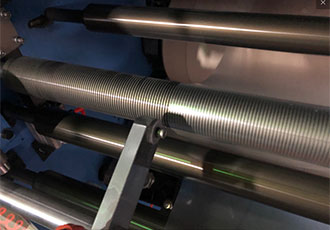

5.Double metal roll glue coating system: High precision treatment double rolls coating system with Rubber blade (metal blade) that could be available for various glue, and also save a lot glue (3-4g/m2)

6. Drying and Heating System: Bulk 800mm diameter drying roll with Teflon coating, that could bring the highest glue drying effect, large heating roll by electromagnetic heating plus oil heating, guarantee the heating efficiency and make sure laminating quality when run in high speed.

7.Main Machine Body: Thicken machine wall (25mm thickness) enhances stability and for long time service life.

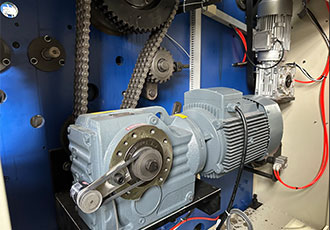

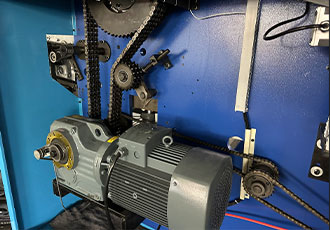

8. Three rows chain Driving System: Special structure design in minimum transmission line, adopts three rows chain to drive the laminating unit to guarantee the high laminating speed with low noise.

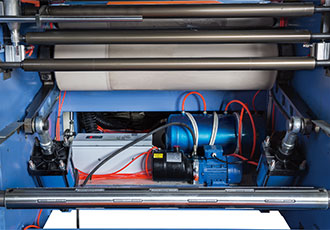

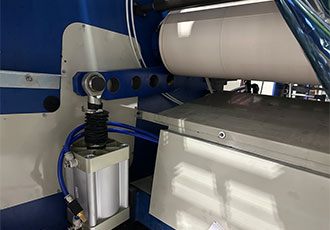

9. Pneumatic Pressure System: fully pneumatic system to control the laminating pressure, the pressure would highly uniform and easy to adjust.

10.Man-Machine Interface System: Advanced 10inch color screen with PLC system makes the operation easy and convenient.

11. Automatic tension system: The machine comes with auto tension system to control the jumbo materials. And adopts independent tension system for film roll.

12. Rewinder: Thicken machine body to support big rolls and make sure the reminded materials roll edge flat and smooth

|

Model |

ZFM-1700J |

|

Max. width |

1650mm |

|

Working speed |

80-100m/min |

|

Paper thickness |

80-500gsm |

|

Total power |

68kw |

|

Diameter of unwinding |

1400mm |

|

Diameter of rewinding |

1400mm |

|

Overall dimension |

7500*3500*3000 |

|

Machine weight |

11000kg |

|

1. Shaftless unwinding system with ultrasonic Web guide system Shaftless unwinding system that could be suitable for 3inch and 6-inch paper core, and easy for loading and unloading. Hydraulic pressure system that could support load heavy and big jumbo roll ultrasonic web guide, that mostly advance technology with high precision and sensitive. |

|||

|

|

||

|

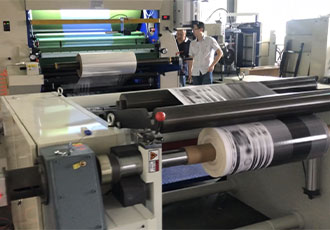

2. Laminating Unit Heating roller by electromagnetic heating plus oil heating, double heating systems guarantee the prompt pre-heating and make the temperature to 180℃ and can keep constant temperature in high speed laminating. Pressure rubber roller controlled by fully pneumatic system, the pressure would highly uniform and easy to adjust without bubbles、spots or wrinkle. |

|||

|

|

||

|

3. Glue Coating unit High precision processing double metal rolls glue coating system to support low glue consumption (2-4g/m2) Adjustable glue coating quantity to match different materials and running speed. Outside moving glue coating unit: the glue coating rolls are moved outside of machine (drying unit), so the glue will not dry on rolls because of hot air. |

|||

|

|

||

|

4. Drying system Special design IR lamps set inside of drying roll, that make the glue drying fast but with low power consumption. Blowing fans plus exhaust fan recycle the hot air and energy saving. Teflon coating surface to uniform the temperature and glue Sticking prevention that easy for cleaning and maintain |

|||

|

|

||

|

5. Film Unwinding Install air shaft for film unwinding with auto tension controller. Special design for big diameter film roll and the roll can be adjusted to right and left. |

|||

|

|

||

|

6. Waste Film Slitting and Rewinding Moveable waste film rewinding to modify the jumbo film width that can fit for paper sheet size. |

||||

|

|

|||

|

7. Three rows chain with gear box driving system For the main laminating part adopts three rows chain with gear box driving system, that support machine run in high speed with high precision and low noise. This structure also support machine run in long time but keep stability. |

|||

|

|

||

|

8. Fully Pneumatic laminating pressure system The machine use pneumatic pressure for laminating pressure that would guarantee laminating effect, also have sensitive pressure adjustment and keep machine running in clean condition. |

|||

|

|

||

|

9. Rewinder System Adopt PLC and touch screen system to control the tension. And use hydraulic loading and unloading system. Variable frequency motor to adjust the speed with high presison |

|||

|

|

||

Max. width 1250mm

Up to 80-100m/min

Max. width 1450mm

Up to 80-100m/min

Max. width 350mm

Up to 0-60m/min

Max. width 500mm

Up to 0-70m/min