1. Automatic front lay to adjust the overlapping, that is controlled by PLC system

1. Frequency converter with infinitely variable speed, which ensures the speed adjustment convenient and efficient, and makes the machine run stably and quietly.

2. Enlarged size of chromed heating roller (φ320mm) is mounted with built-in oil heating system which provides balanced laminating temperature and owns excellent temperature persistence.

3.Hydraulic system for laminating

4. Removable air shaft with passage, that is convenient for loading and unloading the film rolls, and easy for cleaning the machine.

5. Sets of serrated perforating wheels provide different choices for different specifications of sheets and film.

5. Color man-machine interface with PLC control system, easy for operation.

6. orrugated delivery system, to make thin paper flat and smooth.

7.Vibration paper stacker table make the paper pile collect tidy.

|

Model |

BFM-920 |

|

Max Paper Width |

900mm |

|

Laminating Speed |

0-30m/min |

|

Paper Thickness |

105-500gsm |

|

Temperature |

≤130℃ |

|

Gross Power |

19kw |

|

Overall Dimensions |

4000×1900×1700mm |

|

Weight |

1800kgs |

|

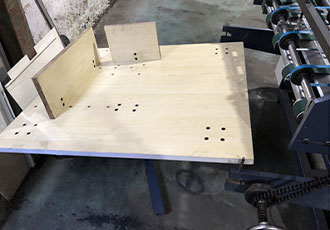

1. Manual Paper Feed Table With Front Lay. Front lay controlled by PLC system, that will adjust overlapping automatically, just need set the overlap length in touch screen, easy for operator. |

|||

|

|

||

|

2. Laminating Unit With Bulky Heating Roll And Rubber Roll Big diameter heating roll make the laminating in high speed and bring ideal laminate result. |

|||

|

|

||

|

3. Removable Air Shaft And Perforating Blade Removable shaft is convenient for loading and unloading the film roll, Perforating blade offer multiple sheeting system. |

|||

|

|

||

|

4. Passage Humanized design of passage, that easy for loading film roll and cleaning machine. |

|||

|

|

||

|

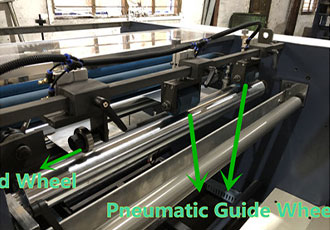

5. Paper Guide Wheel And Paper Vacant Sensor Pneumatic guide wheel make paper delivery smoothly, vacant sensor is safe for operating, the machine will turn off automatically if vacant paper sheet. |

|||

|

|

|

||

|

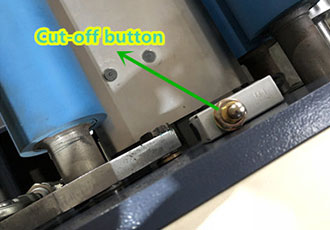

6. Safety Cover With Cut-Off Button Safery cover can effectively prevent operator wrapped in, and cut-off button will trun off the machine if open the cover. |

|||

|

|

||

|

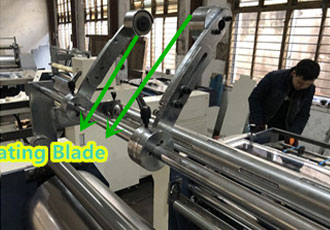

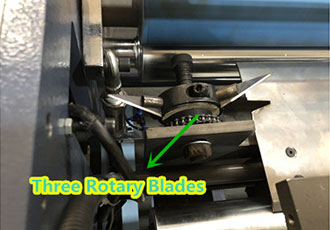

7. Pneumatic Sheeting Roll And Rotary Blade Three rotary baldes with pneumatic sheeting roll make every paper separate without margin, that can easy for next process. |

|||

|

|

||

|

8. Touch Screen With PLC And Schneider Electrical Components Schneider Electrical makes machine run in stable station and touch screen with PLC make the operation very easy. |

|||

|

|

||

|

9. Drive System And Auto Pressure Automatic pressure regulation system controlled by hydraulic. |

|||

|

|

||

|

10. Corrugated Delivery System Corrugated delivery system make paper delivery smooth and keep paper sheet flat. |

|||

|

|

||

|

11. Vibration Paper Stacker Table Vibration stacker make the paper pile collect tidy and easy for operator. |

|||

|

|

||

Max. width 1150mm

Up to 80-100m/min

Max. width 700mm

Up to 0-30m/min

Max. width 1050mm

Up to 0-30m/min

Paper Size 1050mm*1000mm

Up to 5-40m/min