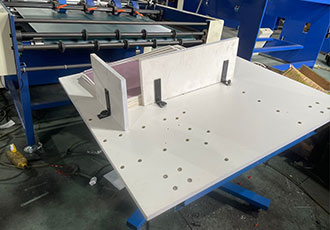

1.Pneumatic front lay to control the overlap automatically with high precision, which is easy for hand feed sheet operation.

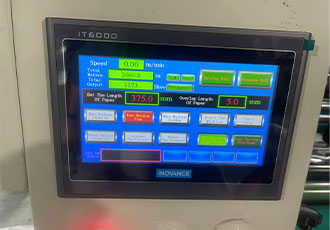

2.Color man-machine interface with PLC system, easy for operation.

3.600mm diameter drying roll heated by 18 pieces strength ir lamp with specially layout, which can pre-heat fast and save 1/3 energy.

4.Heat conducting oil roller inner circulation system with 320mm diameter, makes temperature uniformity and heat fast.

5.Hot air circulation system, discharge water vapor and 30% energy saving.

6.Bulky press roll guarantee the laminating effect.

7.The main rotating section adopts NSK bearing.

8.Film cutter adopts two types: (1).cut by motor (2). Cut by circular knife.

9. Auto hydraulic pressure adjusting system with manual hydraulic pressure

|

Model |

FM-1050 |

|

Max Paper Size |

1050mm*1000mm |

|

Laminating Speed |

5-40m/min |

|

Lamination Temperature |

30-120℃ |

|

Lamination Pressure |

5-15 mpa |

|

Machine power |

45kw (working power about 18kw/h) |

|

Working power |

15-20kw/h |

|

Overall Dimensions |

7.6m×2.2m×2.3m |

|

Weight |

4000kg |

|

1. Feeding table with Auto Front lay |

|||

|

|

||

|

2. Touch screen with PLC |

|||

|

|

||

|

3. Glue Coating unit |

|||

|

|

||

|

4. Drying and Laminating unit |

|||

|

|

||

|

5. Film Unwinding and Waste material slitting device |

|||

|

|

|

||

|

6. Sheet Cutting unit and Anti curving device |

|||

|

|

||

|

|

||

|

7. Collection table with vibration |

|||

|

|

||

Max. width 900mm

Up to 0-30m/min

Max. width 1050mm

Up to 0-30m/min

Max Paper Size 960x620mm

Paper thickness 120-1500g

Max Paper Size 1100x680mm

Paper thickness 120-1500g